Member-only story

How Did Printing Work in the Time of Gutenberg?

An explanation of printing jargon such as punch, matrix, and type

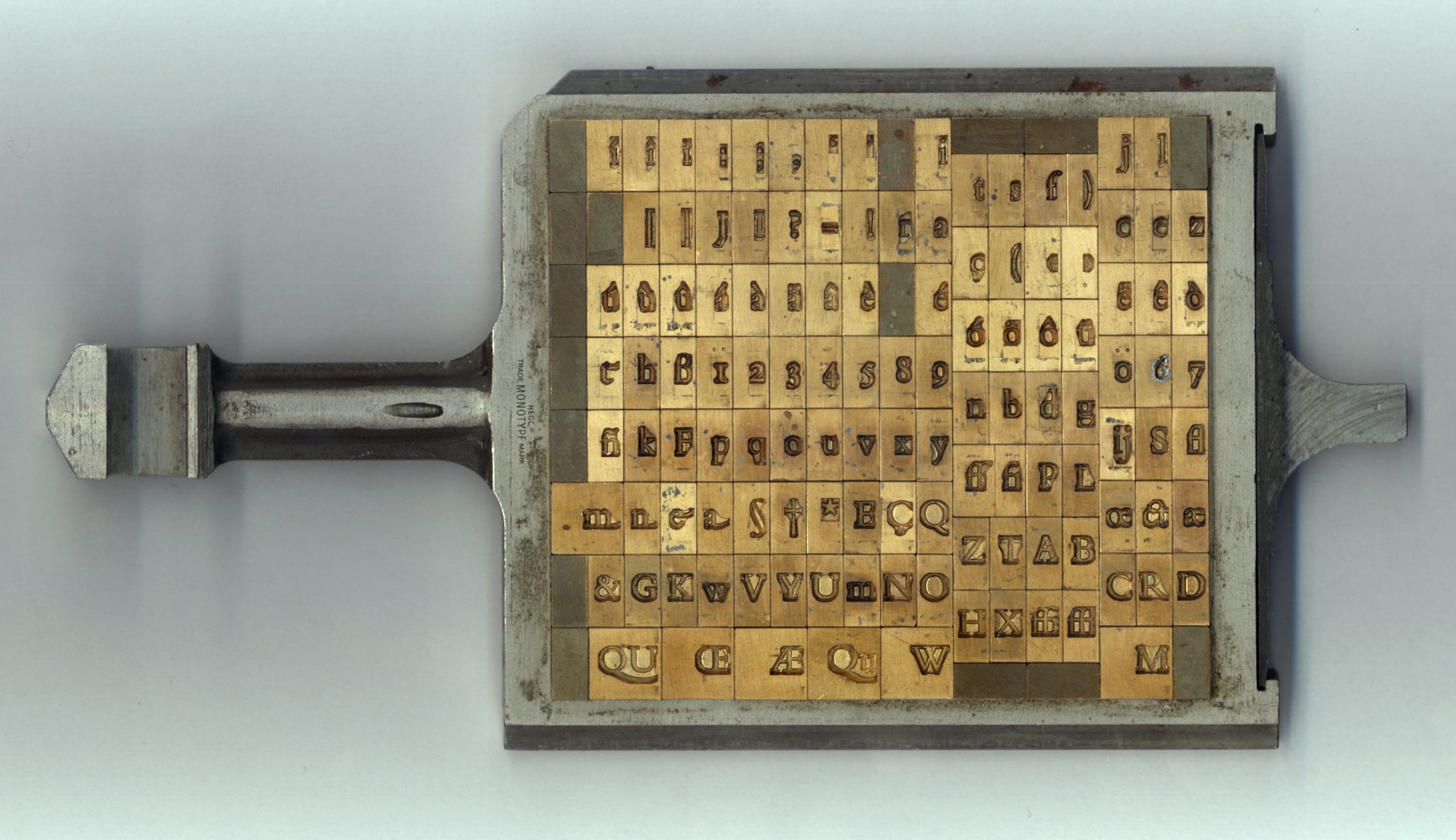

When reading about printing in the time of Gutenberg on wikipedia, it can be hard to understand the terminology. Personally I was confused by the word matrix. Many of us will associate the word matrix with a lattice or table of some sort composed of many elements. I was confused by the image blow, showing a composition case. Because the case contains many elements, I got into my mind that this whole thing was a matrix. That is wrong. Each individual mould of a letter you see in the case below is what we call a matrix.

A matrix represents a single character, not multiple. Why not call it a letter mould and avoid confusion? A matrix isn’t a full mould. It only gives the shape of the letter. If you look at actual types shown below, you can see they are like long square rods. Gutenberg would combine the matrix with a hand mould to create the whole mould for a type. Next he would pour a liquid metal alloy consisting of lead, tin, and antimony into the mould. The alloy cools quickly, and out comes a lead type similar to the ones seen below: Square metal rods with typefaces on them.

We must also appreciate that printing technology has evolved a lot over the years. The composition case I showed was not used by Johannes Gutenberg. It got used from the 1950s in what we call hot metal typesetting. Gutenberg would have typeset pages by composing movable types on a composable stick, as shown below (or in similar fashion).

Next the metal types would get inked with ink balls. Once the surface of all metal types are covered in ink, a paper would be placed on top. The paper is secured in a frame, so it doesn’t move around. A screw press is then used to press the paper against…